Application, characteristics and applicable range of SiC polishing powder

[ 2017/6/19 ]

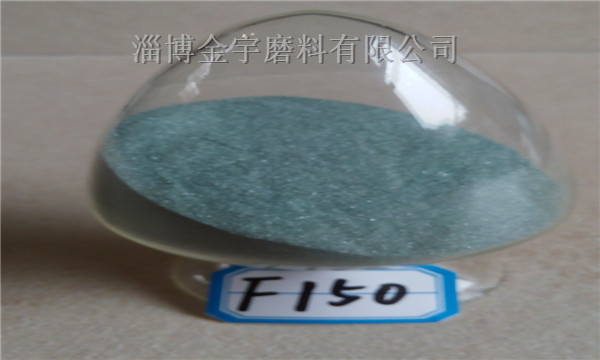

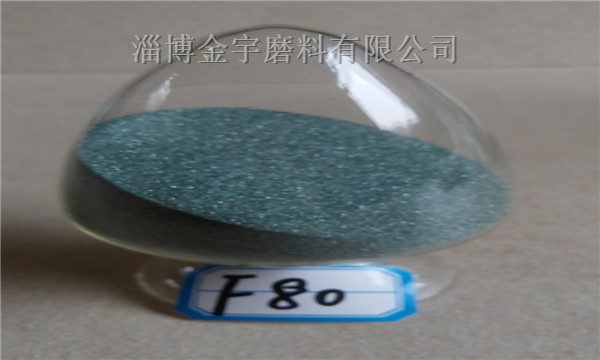

Green silicon carbide is green, high hardness, strong cutting ability, stable chemical properties, good thermal conductivity. The primary purpose: solar wafers, semiconductor wafer, wafer polishing, crystal cut grinding; ferrite; fine polishing ceramics, special steel; consolidation and coated abrasives, cutting, grinding and polishing can be free; grinding glass, stone, agate and high-grade pearl gem is non metal materials, but also can the production of high-grade refractory materials, engineering ceramics, heating elements and thermal elements, wearability or the thermal effect in the coating. The first guess features: high packing density, grinding ability, high hardness, cutting ability, grain size distribution and uniform convergence; high temperature resistance, high strength, thermal shock resistance, good function, high temperature directly heating material. Scope: green silicon carbide abrasive are widely used in a variety of occupation, jade stone polishing, glass, steel, plastic, electronics, solar cut, die forging, refractory materials, aerospace and defense. Build roads., occupation, clothing (denim sandblasting), beauty, metal grinding, make appropriate ceramic grinding wheel of the grinding block. Physical and chemical objectives: Micro shape is six square crystal, silicon carbide, silicon carbide content of more than 98%, Mohs hardness is 9.2, higher than corundum, and second only to diamond, cubic boron nitride and boron carbide. Green silicon carbide powder produced by the company is green and has six sides crystal structure. It has many advantages, such as good wear resistance, high hardness, strong cutting ability, stable chemical properties, high thermal conductivity and small coefficient of thermal expansion. Size: 60# 80# 100# 120# 150# 180# 240# 320# 400# 500# 600# 800# 1000# 2000#, 3000# 4000# 6000# 8000# 10000# and so on in the use of coarse and fine abrasive: mainly used for solar silicon, piezoelectric crystal cut and grinding, also used for grinding and polishing of all kinds of stone, iron, glass, ceramics, jade jewelry and other occupation in. Application of Engineering Ceramics: silicon carbide products mainly used in reactive sintering (RBSiC) technology, recrystallization (RSiC) technology and pressureless sintering (SSiC) technology. Such as the roof plate, under high temperature conditions using the beam, roller, nozzle and other high temperature kiln, heat resistance, wear resistance and corrosion resistance of mechanical seals, all kinds of sliding bearing and rolling bearing, various body parts, all kinds of electric heating elements and automobile brakes etc.. DPF made from silicon carbide powder, as a gas purification filter material, is a necessary component of the new automotive exhaust purification, and has a broad application prospect. In addition, it can also be used for bullet proof materials, conductive coatings, internal and external coatings for colorful picture tubes, various vessels, coatings and so on.

- Pre:Zibo refractories, silicon car 2017/6/19

- Next:What are the differences betwe 2017/6/14

Add:Xishan Road, Zichuan District,Zibo City,Shandong Province

Tel: 086-0533-5410788

Fax: 086-0533-5413279

Website: http://www.zibojinyu.com'

Email: zbjinyu2008@163.com

在线客服系统